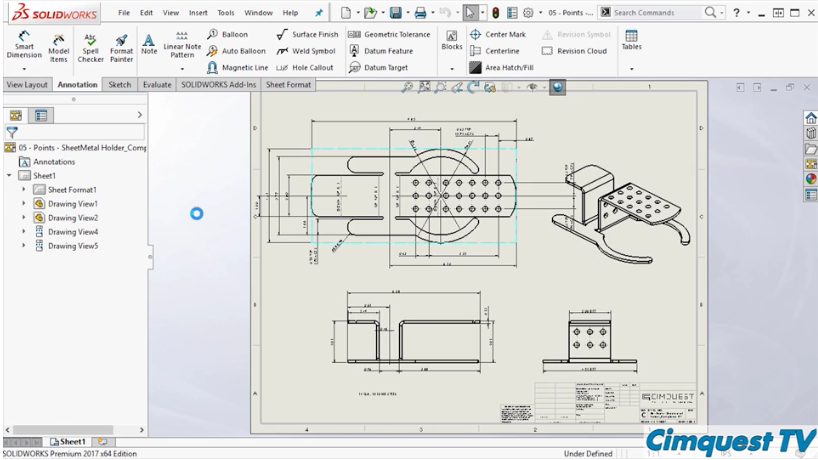

So we have created a video tutorial to demonstrate the process of reverse engineering 3d scanning a part into solidworks using an artec space spider 3d scanner.

Reverse engineering sheet metal parts using solidworks.

Reverse engineering add in for solidworks.

A note on methodology.

Along with part assembly and 2d drawing functionality specialized tools are included for sheet metal weldments surfacing molds product configuration design analysis dfm and cam.

There are specific sheet metal features you can use to create sheet metal bodies quickly.

Set the sheet thickness and default bend radius.

The trick when using 3d interconnect is to add bends specifically using the convert to sheet.

Artec eva is a hand held 3d scanner ideal for making a quick textured and accurate 3d model of medium sized objects such as a human bust or an alloy wheel.

You might also like.

For more information on reverse engineering please visit https goo gl qfejid to learn more about our portable 3d scanners for reverse engineering visit htt.

Welcome to a better and friendlier way to reverse engineering.

Solidworks 3d allows you to quickly create sheet metal part designs using a simple design process saving you time and development costs thanks to specific sheet metal features.

Under sheet metal parameters.

The new 3d interconnect functionality introduced in solidworks 2017 is useful when working with a variety of native non solidworks files including parts that are sheet metal in nature.

Get up to speed quickly and benefit from this powerful 3d design and manufacturing solution.

When cleared the body is consumed by the convert to sheet metal feature.

Here is a preview of the tutorial just fill out the form below to watch the entire video tutorial.

There are a few ways to add sheet metal information to a part referencing an external file.

However in some circumstances when the design requires certain types of geometry you can use non sheet metal feature tools then insert bends or convert the part to sheet metal.

Cam included with an active subscription.

We can use these features to create sheet metal designs with several different methods.

Artec space spider is a hand held 3d scanner designed specifically for cad users and perfect for reverse engineering product design and quality control.

We will focus on the flange method where a sheet metal part is created in the formed state using specialized sheet metal features.

Artec leo is a smart professional 3d scanner.